Design & Use > Heavy Duty Design • Key Features • Moving Heavy Loads

Key Features of TechimpexUSA

Heavy Duty Dollies

TechimpexUSA™ Heavy Duty Dollies Utilize Several Key Features

That Provide Essential Capabilities For Moving Heavy Loads

Low Profile Design

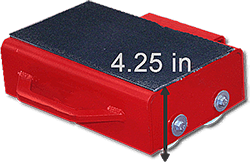

Heavy duty dollies manufactured by TechimpexUSA™ feature a consistent low profile height design across all the available model lineups. Because of the low profile characteristic it only takes a very minimal clearance to position the heavy duty dollies under large loads. We manufacture five basic model lines (RT, SFT, ST, FT, IFT) with over 30 different loading capacity options within those model lineups.

All of those 30+ options maintain the exact same height of 4.25 inches from the floor to the loading surface of the unit. Lifting or raising a large and heavy load higher than absolutely necessary to properly position the heavy duty dollies underneath increases the possibility of instability and potential damage to the load. A minimal clearance attribute is of the upmost importance when Relocating Large Machines.

Durable Urethane Rollers

The highest quality urethane rollers are used on all models of our heavy duty dollies. The durable urethane rollers are extremely tough and long-lasting and excel at providing the non-marking and non-damaging demands of sensitive flooring.

Various heavy duty dollies models use either an SD Roller (Black) or a HD Roller (White). The color difference is only for identification purposes. The high quality urethane formula is the same in both versions. The SD Rollers are used on the lighter load capacity skates & dollies and incorporate a single set of internal roller bearings. The HD Rollers are used on the higher capacity skates & dollies and utilize a double set of internal roller bearings. The bearings in both roller versions are completely sealed and pre-lubricated to ensure years of effective use.

Urethane Rollers That Are “Just Right”

TechimpexUSA™ heavy duty dollies are designed to protect flooring from marking and marring by utilizing high-quality, durable urethane rollers. Each Urethane Roller is sturdy and strong enough to carry thousands of pounds of weight, but still offer the flexibility and “give” to protect the floor and spread out the loading footprint across the flooring surface. Only a material like urethane has the tough, but flexible characteristics for the demands of heavy machinery moving.

To contrast, a solid steel roller would potentially last a lifetime, but the unforgiving steel is only suitable for the hardest surface and will certainly mark and mar most surfaces (especially sensitive ones). Steel rollers are also capable of cracking and gouging concrete under the right circumstances.

On the other hand, a roller that is made of a material that is too “soft” will certainly protect the floor but the material will not stand up to long term use while Moving Heavy Machines. A roller that is too soft will also create a situation where the load is extremely hard to turn and maneuver with the heavy duty dollies.

Our heavy duty dollies utilize urethane rollers that have been designed to find a middle ground between too “hard” and too “soft.” A roller that is “just right” is tough and long-lasting, provides the “give” necessary to protect a range of flooring surfaces and gives the heavy duty dollies adequate handling characteristics.

With consistent, heavy use on rougher surfaces, urethane rollers will eventually develop pits and other surface defects. This type of wear on the rollers after years of frequent use is not a shortcoming of the urethane, but the trade off between being both durable and forgiving. The overwhelming majority of our customers never need replacement rollers, but if the need arises, we always have a full stock of replacement SD (Black) and HD (White) rollers for our heavy duty dollies ready for immediate shipment at a reasonable price. Our unique Bolt On Axle Design (see below) feature makes swapping out a damaged or worn out urethane roller a snap.

Multiple Configuration Possibilities

All of the heavy duty dollies manufactured by TechimpexUSA™ can be interchanged to produce multiple configurations. There is usually a configuration capable of handling any heavy load moving situation. One of the most common configurations is the tried and true, classic, SFT 3-Point System which provides precise steering and control of the heavy duty dollies while under a load.

Another popular configuration option is utilizing multiple RT Rotating Skates around the perimeter of the load. A typical option would be to use four RT units on the corners of a load, providing the most versatile load moving capability.

A third popular option is to use RT Skates with an optional handle attachment in conjunction with a set of FT Fixed Units. This setup provides excellent maneuverability and the introduction of the Fixed FT Models increases the cost effectiveness. Many other mix and match options utilizing heavy duty dollies can produce the right configuration for any Heavy Machine Moving Project.

Friction Pads

The high-grade, robust friction pads included with every model of heavy duty dollies that TechimpexUSA™ offers are an important, but often overlooked design feature. The friction pads are made of a thin, but substantial, super-tough belting material that is virtually indestructible. The purpose of the friction pad is twofold.

First, the friction pad serves as a buffer between the load and the loading surface of the heavy duty dollies to prevent damage to the finish of the load. Second, the friction pad helps keep the load from shifting during a move by providing a "grabbing" surface which serves to keep the load properly located on the loading surface of the heavy duty dollies.

Bolt-On Axle Design

All models of our heavy duty dollies feature an easy-to-use bolt-on axle assembly design. If the need arises for cleaning or replacing the extremely durable urethane rollers, the changeover is simple. A couple of 1/2 inch wrenches are all that is needed to make quick work of the replacement process. This can be a great convenience when using the heavy duty dollies on a moving project away from the shop.

Carrying Handles

RT Rotating Models feature a handy and rugged handle slot for carrying and positioning the units. On the RT models the handle slot provides a way to carry the units and avoids potential user injury that can occur when the RT rotating caster units rotate downward. The larger rated weight capacity RT units feature a handle slot that can accommodate two hands allowing the unit to be carried by two people. The handles are also convenient and effective options for attaching chains, ropes and other items that might help facilitate a heavy machinery move.

IFT Single Skates and FT Fixed Dollies feature a thick, beefy handle that is solidly welded to the frame of the heavy duty dollies. The handle provides a convenient and necessary method to transport the units. It also provides a way for the user to position the units under a heavy piece of equipment. As with all our heavy duty dollies, we overbuild the handle assembly as well and this makes it a perfect place to wrap chains, straps and other rigging accessories in order to ensure a successful machinery move.

Easy Access Adjusting Set Screw

FT Fixed Models incorporate a fully adjustable alignment bar. The alignment bar provides a range of possible widths in the distance between the units connected along the bar. The distance between each unit is fixed in place with a simple, robust set screw (actually a 3/4 bolt). The easy-to-adjust set screw is conveniently located on the back of each IFT Skate. The easy access to the adjusting screw provides the user with a quick and convenient way to vary the distance between the individual units of the FT Models.