Machine Skates > RT Rotating Series • SFT 3-Point Series • ST Steerable Series • FT Fixed Series • IFT Single Series

Heavy Duty Machine Skates Made in the USA

by TechimpexUSA

Heavy Duty Machine Skates Manufactured by TechimpexUSA™ Feature

Multi-Configuration, Low-Profile Designs for Rolling, Moving & Rigging

Large Equipment, Loads & Machinery

Heavy Duty Machine Skates Model Options

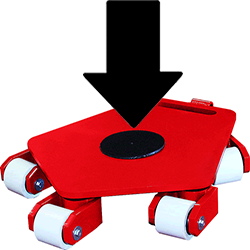

RT Rotating Models Provide the Most Versatile Option for Heavy Machine Moving. A Set of Four Rotating Machine Moving Skates Give the User a Variety of Load Contact Points with Maximum Maneuverability.

SFT 3-Point Models Utilize the Combination of a ST Steerable Skate Matched with a Set of FT Fixed Skates to Create Three Points of Contact with the Load. This is a Classic Machine Skate Configuration that has Stood the Test of Time.

IFT Single Models are the Most Cost Effective Model for Moving a Large and Heavy Machines. IFT Single Machine Skates have Impressive Weight Capacity Relative to Their Size, Making Them the Best Choice for a Simple Move.

ST Steerable Models are Designed with a Rotating Swivel Pad Allowing Them to Steer the Heavy Machine Being Moved. The Heavy Duty Handle & Eye Hook Feature Provides Push and Pull Capability as Well. ST Steerable Machine Skates are Typically Paired with FT Skates for a SFT 3-Point Series Configuration.

FT Fixed Models are Designed to be Used in Combinations of Two or More Cassettes Along an Adjustable Length Alignment Bar. Fixed Machine Skates Offer Straight-Line Movement Making Them a Go-To Option for Simple Moves. FT Skates are Typically Paired with ST Models for a SFT 3-Point Skate Configuration.

Toe Jacks are Used to Lift and Raise Heavy Machines Above the Flooring Surface so that Machine Skates can be Positioned Under the Load. TechimpexUSA™ Mainly Distributes a Bottle Style Toe Jack but Other Styles & Models Can be Sourced as Well.

Heavy Duty Machine Skates Design & Use Features

Heavy Duty Design Elements Ensure

Rugged, Dependable, Long-Lasting Machine Skates Use

Key Features Provide Essential Capabilities For Moving Heavy Machines and Other Loads

Moving Heavy Machines Successfully Includes Several Important Technical and Planning Factors

More About Heavy Duty Machine Skates by TechimpexUSA™

TechimpexUSA™ is an American Manufacturer Producing Heavy Machine Moving Skates Right Here in Texas. We Employ American Workers and Utilize American Suppliers, Helping to Keep Our Domestic Economy Strong and Independent.

TechimpexUSA™ Manufactures High-Quality, Long-Lasting Machine Skates. We Stand Behind Our Machine Skates With an Exclusive 10-Year Warranty. We Have Developed Simple & Straightforward Designs That Keep Our Customers Productive.

TechimpexUSA™ Offers Our Customers American-Made, High-Quality, Reliable Machine Skates at a Fair Price. We are Both the Manufacturer and the Seller so our Heavy Machine Skates are High-Grade and Cost-Effective.